In today’s manufacturing sector, sensors are essential for monitoring the performance of various processes and machine tools. Sensors also play a vital role in the MARS project.

Not only sensors collect data to establish normal baseline levels of operation, but they are also important tools to detect even the slightest fluctuations in performance. This data is instrumental in enabling predictive maintenance, a proactive approach that helps prevent downtime and ensures equipment remains operational.

A critical component of this sensor ecosystem is real-time communication and connectivity.

In this edition of the article series, we will have a closer look on the standalone sensor solution called PROFILO developed by MARS consortium partner STIL.

Addressing key challenges

During delivering the surface measurement with sensors in the MARS project, STIL encountered significant challenges in integrating an optical sensor into a machine tool:

- Robust & Waterproof sensor is needed

- Need to protect the sensor against oil & particles

- Need to clean the part before the measurement

- Need to compensate temperature variations

- Need for a vibration free motion & control

- Need enough room for sensor integration

PROFILO: the standalone solution

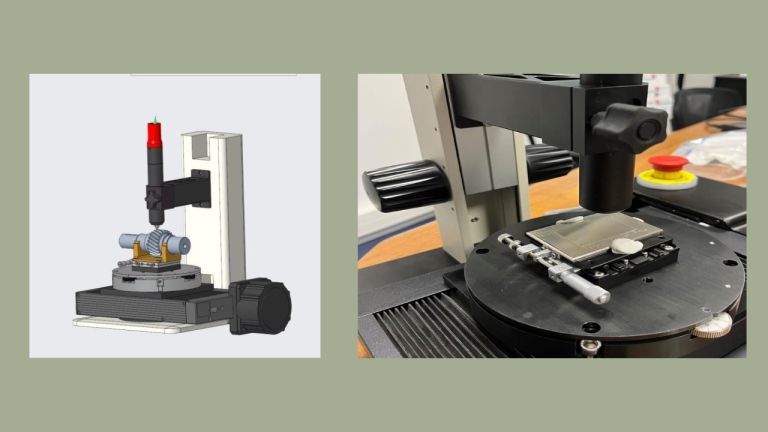

To address these challenges, STIL developed a standalone solution called PROFILO, positioning the sensor outside the machine.

Prototypes and integration tests involved designing the product holder using 3D printing (yellow part), resulting in a customized component (service). Potential clients include manufacturing partners and machine tool users (industrial partners). While the primary focus is on metal manufacturing, the solution is adaptable to various materials and surfaces. The system also incorporates motion control to simulate machine movements.

This solution adheres to the ISO 21290 global standard for profile measurements, ensuring compatibility and reliability in various industrial settings.

Next steps: Commercialization in 2024

The next steps involve commercialization, scheduled for September/October (end of Q3) in 2024. STIL plans to attend the 4th edition of Mesures Solutions EXPO (MSE) that will take place at the Cité des Congrès in Lyon on 16th and 17th of October 2024. This event will be an opportunity to promote PROFILO amongst potential clients of the French manufacturing scheme.

Are you interested in this standalone solution and want to know more about this?

Or even purchase one PROFILO for your manufacturing machine?

Please contact MARS consortium partner STIL:

Cosimi Corleto c.corleto@stil-sensors.com